ABOUT MERRIFIELD MACHINERY

Sales & Support of CNC Machines Since 2007

Since 2007, Merrifield Machinery Solutions has been delivering the most innovative tools and services to Michigan’s largest manufacturers. Our goal is to help our customers make sound capital investments, control their overall costs and extend the life of their equipment—all while meeting their production demands. We’re proud to be one of the most trusted machine tool companies in the state.

To Request a Quote

(248) 494-7335

17

YEARS IN BUSINESS

3,200

+

HAPPY CUSTOMERS

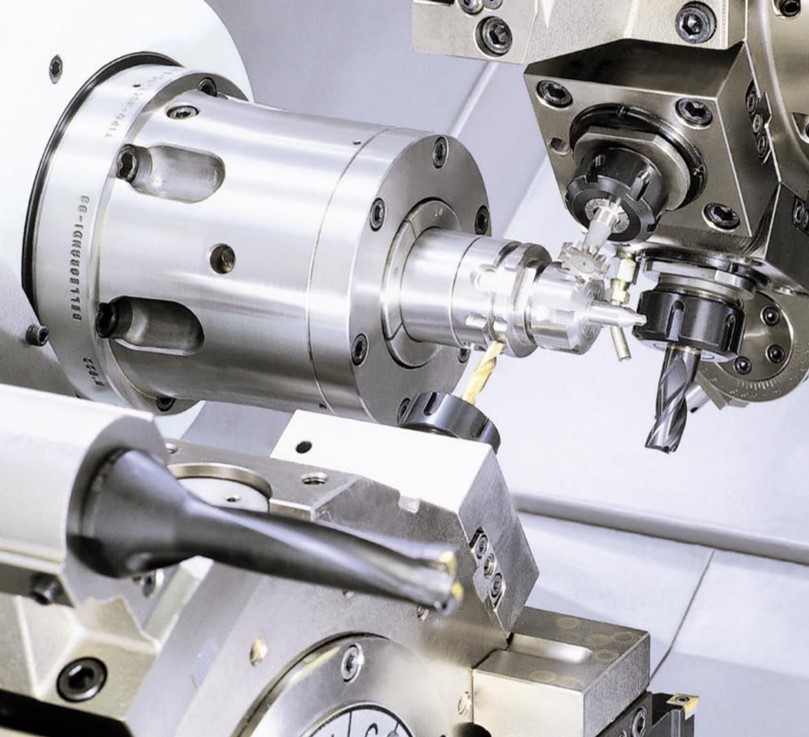

Brands You Know, Quality You Trust

No matter what type of machining centers you’re looking for—we have it! Merrifield carries a wide variety of machining solutions, perfect for your process and industry. Click on one of the OEMs below to see some of the models we currently have available. If you don't see what you're looking for - contact us directly! We'll get you the machine tools you need!

RECENT NEWS

See What's New

Here are some recent posts related to new product offerings, services, industry news, or events that Merrifield Machinery is involved in.

Apr 07, 2024

dwimpari

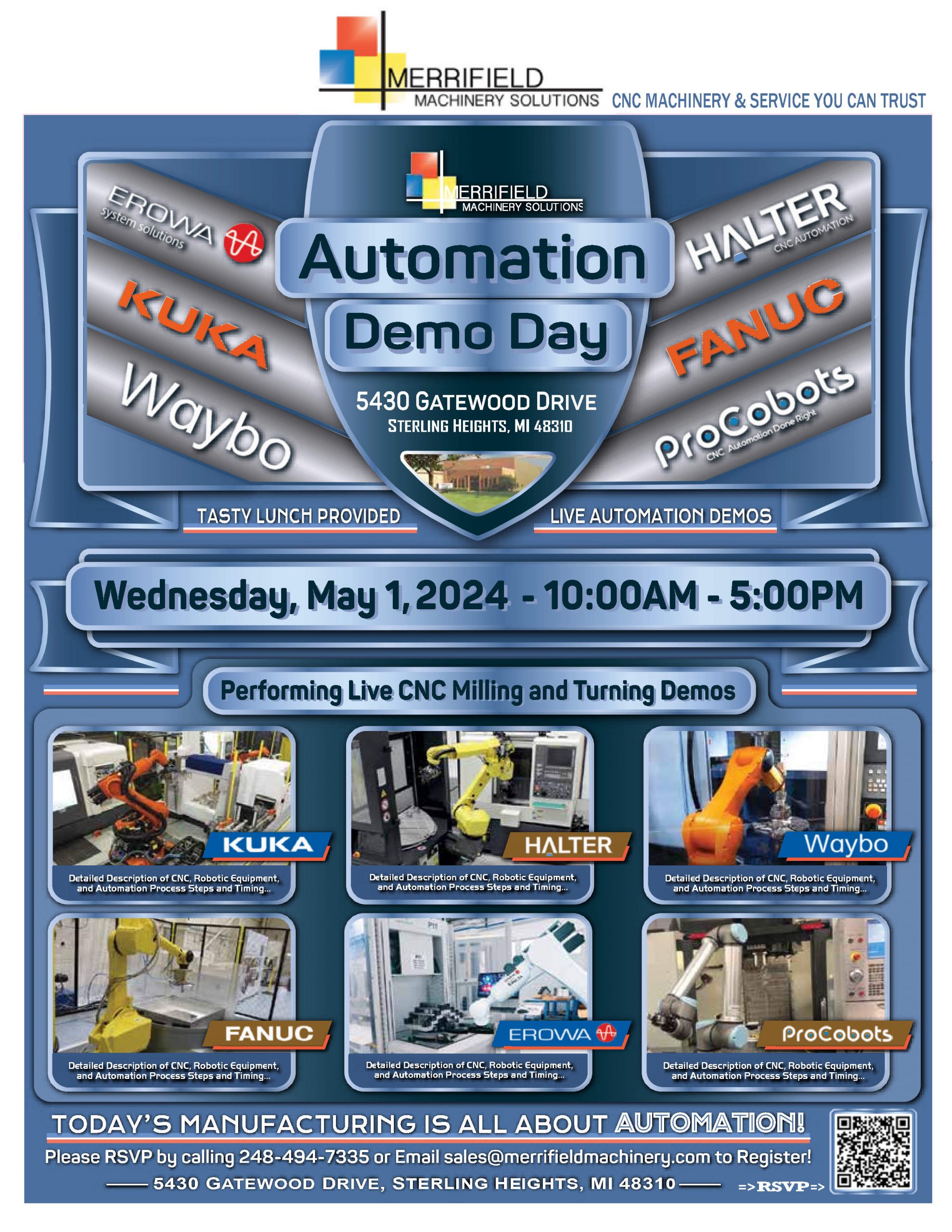

Automation Demo Day – May 1st

Mark your calendars for Automation Demo Day, Wednesday May 1st, 10AM-5PM! We'll have live CNC milling..

Mar 22, 2024

dwimpari

Updated Line Card 03/22/24

Please take a moment to review our current line card, featuring machines from Hurco and Takumi,..

Mar 12, 2024

dwimpari

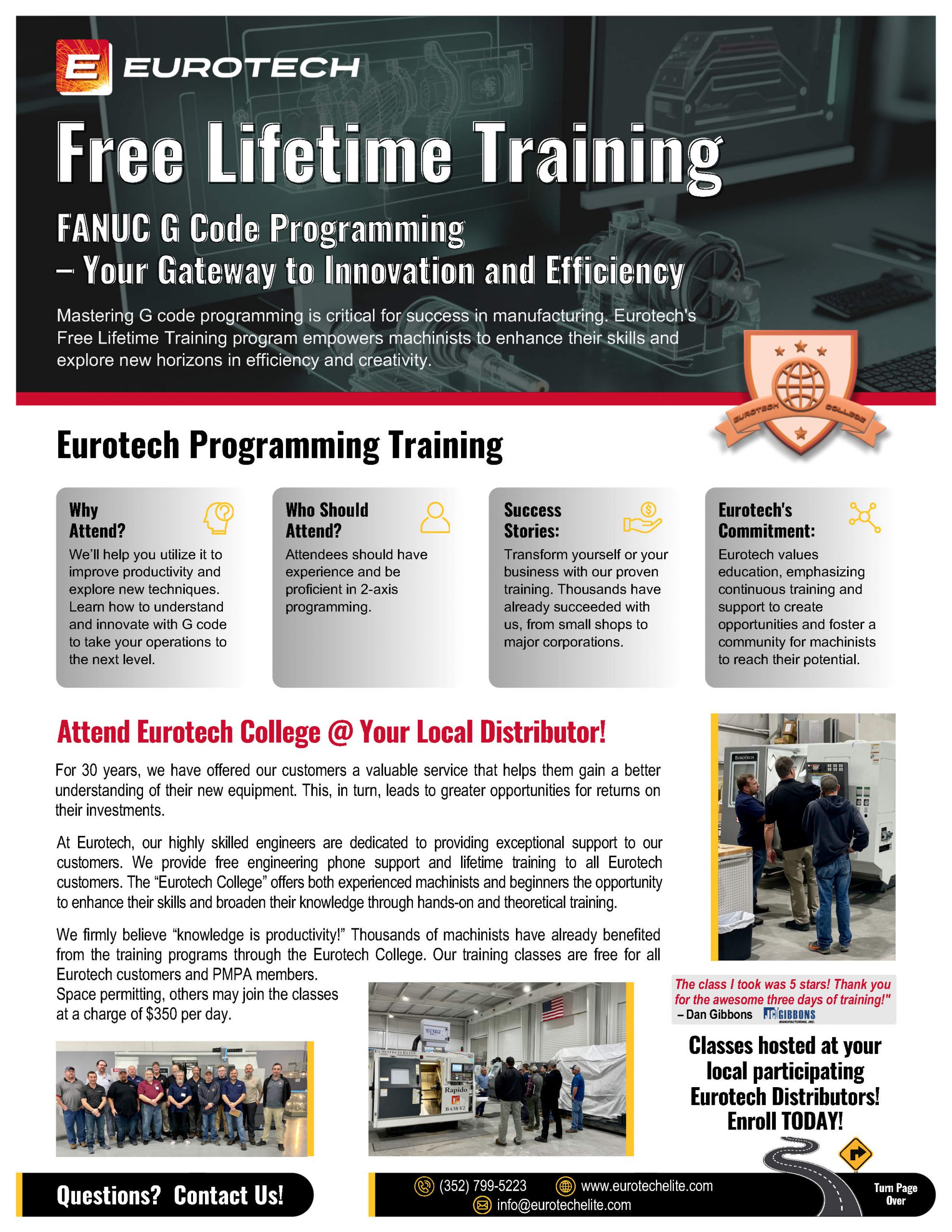

Free FANUC G Code Training – July 16th thru 18th

Merrifield Machinery is proud to be one of the sites for this year's Eurotech University, focusing..